| COMPONENT LOCATION |

| GENERAL DESCRIPTION |

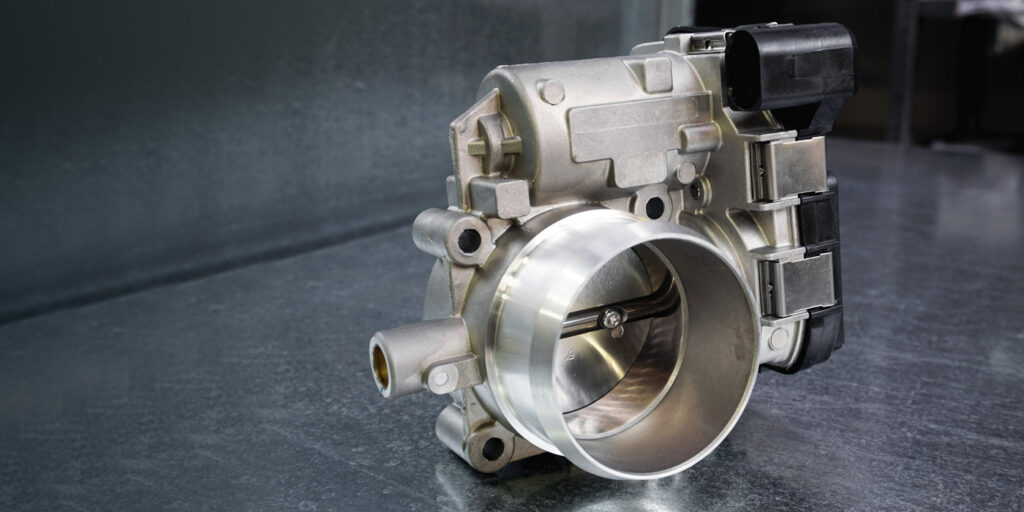

The Electronic Throttle Control(ETC) system consists of the throttle body, Throttle Position Sensor(TPS)1&2 and Accelerator Position Sensor(APS) 1&2. TPS1&2 are sharing the same source voltage and ground. The ECM controls the throttle motor to open and close the throttle valve. The TPS1 output voltage increases smoothly in proportion with the throttle valve opening angle after starting. TPS2 output voltage decreases in inverse proportion with the throttle valve opening angle after starting. The TPS provides feedback to the ECM to control the throttle motor in order to control the throttle valve opening angle properly in response to the driver’s demands.

| DTC DESCRIPTION |

Checking output signals from TPS 1 and 2 under detecting condition, if output signals difference between TPS1 and TPS2 are detected more than 8% for the specified number of times., ECM sets P0221.

| DTC DETECTING CONDITION |

| Item | Detecting Condition | Possible Cause | ||||||||||

| DTC Strategy |

|

| ||||||||||

| Enable Conditions |

| |||||||||||

| Threshold value |

| |||||||||||

| Diagnosis Time |

| |||||||||||

| MIL On Condition |

|

| SPECIFICATION |

| Throttle Opening (°) | Output Voltage (V) [Vref=5.0] | |

| TPS1 | TPS2 | |

| 0° | 0.0V | 5.0V |

| 10° | 0.5V | 4.5V |

| 20° | 0.9V | 4.1V |

| 30° | 1.4V | 3.6V |

| 40° | 1.8V | 3.2V |

| 50° | 2.3V | 2.7V |

| 60° | 2.7V | 2.3V |

| 70° | 3.2V | 1.8V |

| 80° | 3.6V | 1.4V |

| 90° | 4.1V | 0.9V |

| 100° | 4.5V | 0.5V |

| 110° | 5.0V | 0.0V |

| DIAGNOSTIC CIRCUIT DIAGRAM |

| SIGNAL WAVEFORM & DATA |

Fig.1) Normal data & waveform of TPS1 & TPS2 with no accel padal depressed under IG ON condition

Fig.2) Normal data & waveform of TPS1 & TPS2 with accel padal depressed under IG ON condition

Fig.3) Abnormal data of TPS1 & TPS2 under open condition

| MONITOR GDS DATA |

| 1. | Connect GDS to Data Link Connector(DLC). |

| 2. | IG “ON”. |

| 3. | Select “DTC” button, and then Press “DTC Status” to check DTC’s information from the DTCs menu. |

| 4. | Read “DTC Status” parameter.

|

| 5. | Is parameter displayed “Present fault”?

|

| TERMINAL AND CONNECTOR INSPECTION |

| 1. | Many malfunctions in the electrical system are caused by poor harness and terminals. Faults can also be caused by interference from other electrical systems, and mechanical or chemical damage. |

| 2. | Thoroughly check connectors for looseness, poor connection, bending, corrosion, contamination, deterioration, or damage. |

| 3. | Has a problem been found?

|

| COMPONENT INSPECTION |

| ■ Check TPS |

| 1. | IG “ON” |

| 2. | Monitor signal waveform of TPS by stepping on and off the accellerator padel on GDS Specification :

Fig. 1) Normal waveform of TPS1 & TPS2 with no accel padal depressed under IG ON condition Fig. 2) Normal waveform of TPS1 & TPS2 with accel padal depressed under IG ON condition | |||||||||||||||||||||||||||||||||||||||||

| 3. | Is the measured signal waveform O.K ?

※ Procedure of ETS Initialization

|