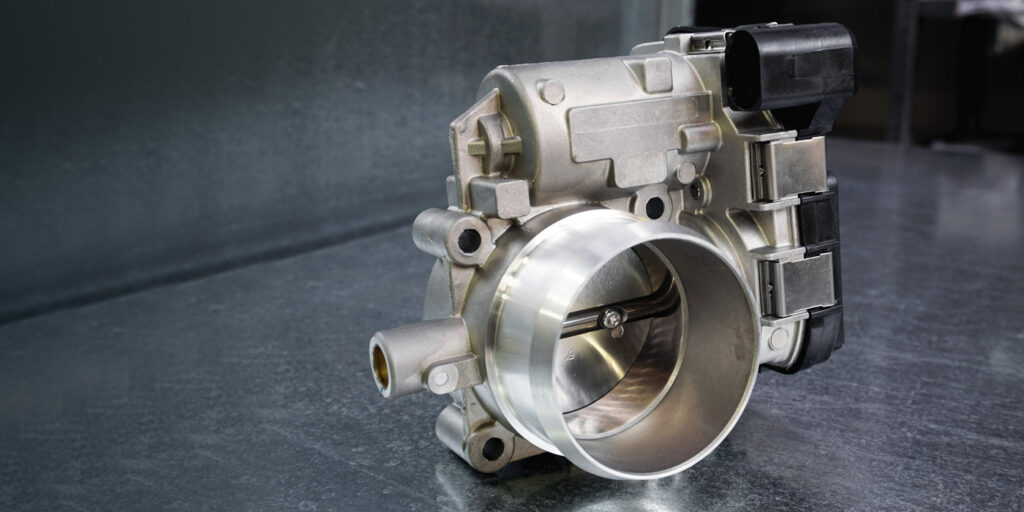

| COMPONENT LOCATION |

| GENERAL DESCRIPTION |

The ECM provides a 5 volt reference voltage to Throttle Position Sensor 1(TPS1). The ECM monitors reference voltage deviation from the power supply circuit of the sensors.

| DTC DESCRIPTION |

Checking the voltage from sensor power supply every 1.87 sec. under detecting condition, if the value within detecting condition lasts for more than 0.2 sec., ECM sets P0641.

| DTC DETECTING CONDITION |

| Item | Detecting Condition | Possible cause | ||||||

| DTC Strategy |

|

| ||||||

| Enable Conditions |

| |||||||

| Threshold value |

| |||||||

| Diagnosis Time |

| |||||||

| MIL On Condition |

|

| DIAGNOSTIC CIRCUIT DIAGRAM |

| MONITOR GDS DATA |

| 1. | Connect GDS to Data Link Connector(DLC). |

| 2. | IG “ON”. |

| 3. | Select “DTC” button, and then Press “DTC Status” to check DTC’s information from the DTCs menu. |

| 4. | Read “DTC Status” parameter.

|

| 5. | Is parameter displayed “Present fault”?

|

| TERMINAL AND CONNECTOR INSPECTION |

| 1. | Many malfunctions in the electrical system are caused by poor harness and terminals. Faults can also be caused by interference from other electrical systems, and mechanical or chemical damage. |

| 2. | Thoroughly check connectors for looseness, poor connection, bending, corrosion, contamination, deterioration, or damage. |

| 3. | Has a problem been found?

|

| POWER CIRCUIT INSPECTION |

| ■ Check voltage |

| 1. | IG “OFF” and disconnect ETC Motor & TPS connector. |

| 2. | IG “ON” |

| 3. | Measure voltage between TPS power terminal of ETC Motor & TPS harness connector and chassis ground.

|

| 4. | Is the measured voltage within specification ?

|

| ■ Check short in power harness |

| 1. | IG “OFF” and disconnect ETC Motor & TPS connector and ECM connector. |

| 2. | Measure the resistance between TPS power and ETC motor (+) terminals of ETC Motor & TPS harness connector.(Measurement “A”) |

| 3. | Measure the resistance between TPS power and ETC motor (-) terminals of ETC Motor & TPS harness connector.(Measurement “A”) |

| 4. | Measure the resistance between TPS power and TPS ground terminals of ETC Motor & TPS harness connector.(Measurement “B”)

|

| 5. | Is the measured resistance within specification ?

|